When looking to increase storage capacity through vertical space utilisation, the Narrow Aisle Racking (NAR) and Very Narrow Aisle (VNA) Racking stand out as two compelling choices. Their names do suggest similarities, however it’s important to recognise the distinct characteristics and functionalities between the two systems. Understanding these differences is crucial for making an informed decision enabling you to select the right system tailored to your space and operational needs.

Exploring narrow aisle systems

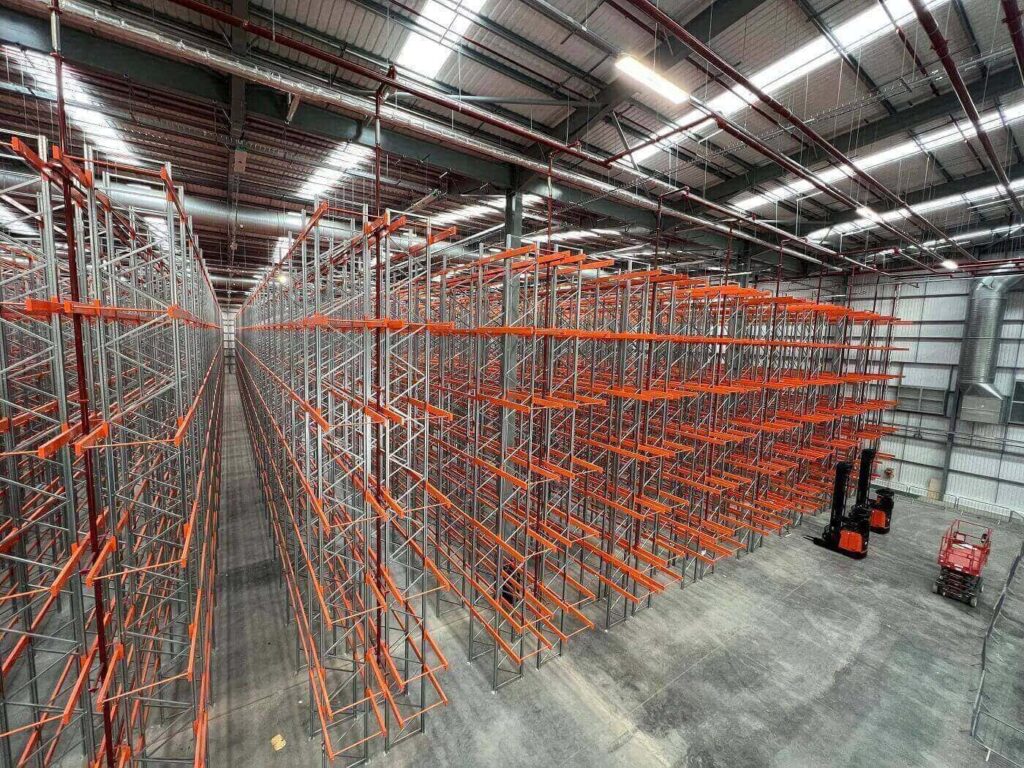

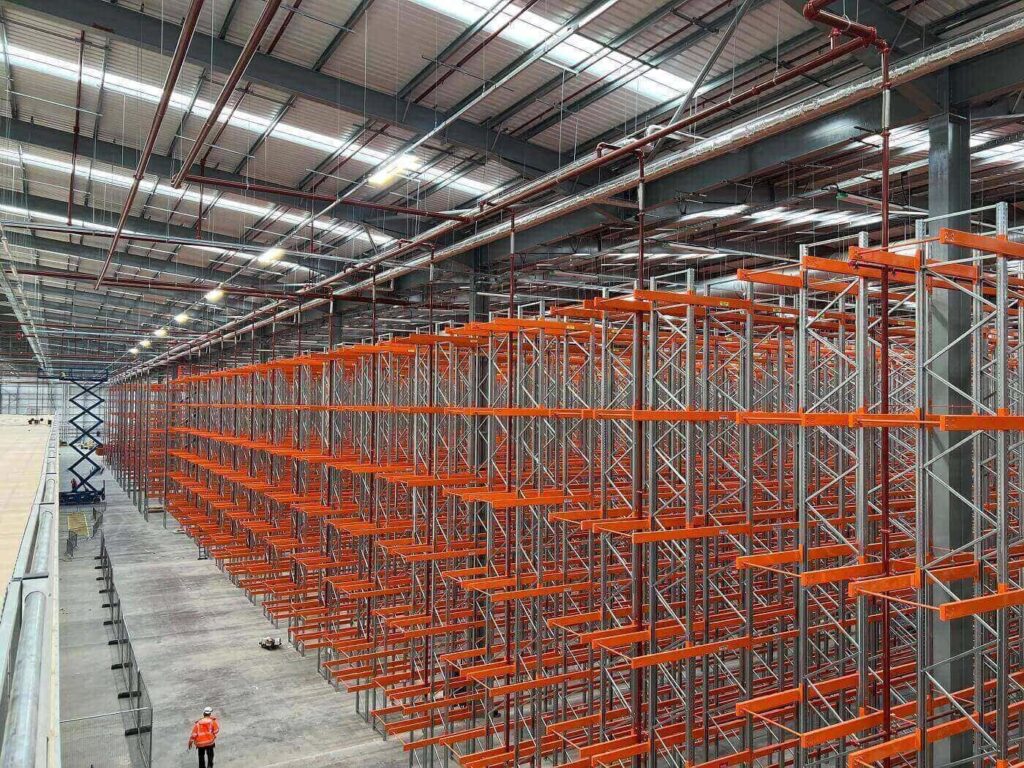

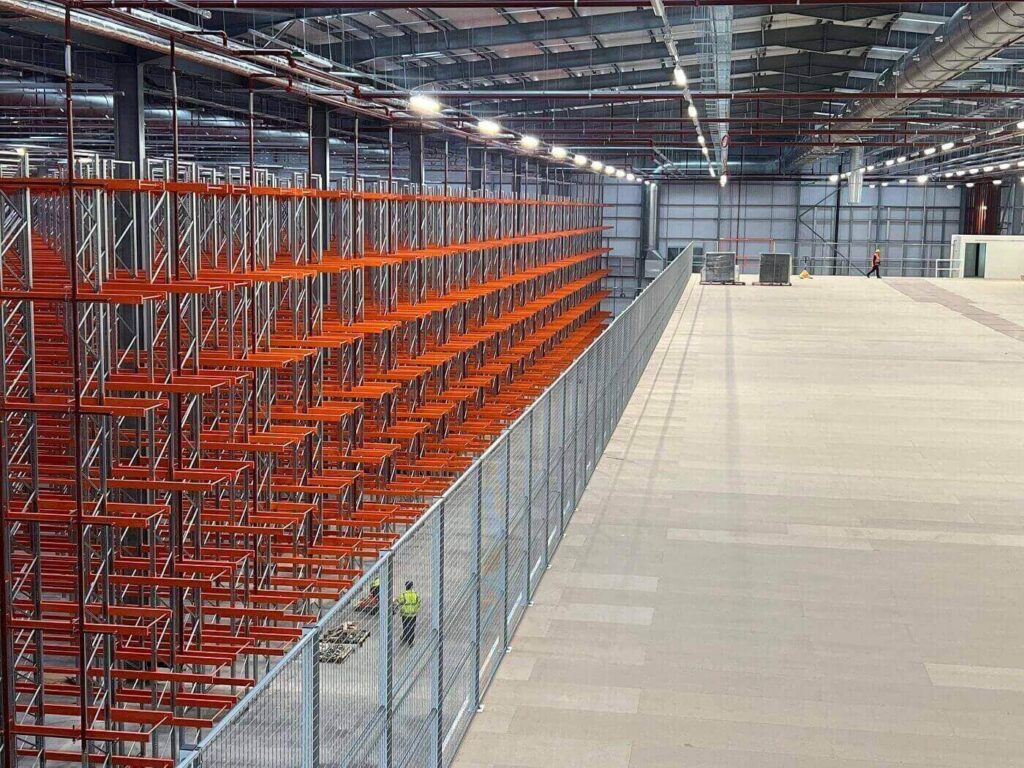

Tall warehouse spaces present great opportunities to fully utilise vertical space and the narrow aisle storage configurations can facilitate this by employing taller racks and slimmed down aisle widths. When compared to a standard wide aisle racking configuration, the narrow aisle system utilises more rows whilst incorporating a higher number of levels, helping to avoid chaotic situations such as lost pallets or warehouse congestion. Instead, the functionality of the floor space is replicated multiple times without expanding the overall footprint, making it a notable advancement in space utilisation.

The variances between NAR and VNA systems

NAR and VNA racking systems are designed for maximum vertical space utilisation and maximum floor area utilisation whilst still giving 100% immediate pallet retrieval, however they do exhibit individual traits. Here are five key areas where disparities emerge between the two systems:

1.) Aisle Width

Narrow Aisle Racking (NAR) – The aisle width of a standard wide aisle racking system would usually be around 3.5-4 metres whilst the NAR system can have an aisle width of around 2.9 metres.

Very Narrow Ailse (VNA) – When compared to the NAR system, the aisle with can be much narrower, to as little as 1.5 metres.

2.) Forklift Trucks

Narrow Aisle Racking (NAR) – The reduced aisle width can accommodate a standard sized truck with high reaching capacity to enable access to the highest pallets. The truck is also able to turn within the aisle, whilst a sideways seating position offers enhanced visibility.

Very Narrow Ailse (VNA) – VNA trucks are generally used in taller systems and use wire guidance, so it is impossible for the operator to hit the racking with the truck. Because of the “clever” forks the truck has no need to turn within the aisle, therefore the aisle and truck can be same width.

3.) Storage Density

Narrow Aisle Racking (NAR) – The narrower aisle width in NAR accommodates fewer rows compared to the VNA system. However, NAR enables more runs of racking within a given floor area than traditional wide aisle racking, making it a highly space-efficient storage option in comparison to standard racking setups.

Very Narrow Aisle (VNA) – With a much narrower aisle width than NAR, the VNA allows for a higher quantity of runs of racking per square metre, making VNA the most highly dense storage option.

4.) Cost

Narrow Aisle Racking (NAR) – Generally, the initial investment for narrow aisle racking is lower compared to VNA racking which consists of more racking components whilst requiring much more specific handling equipment such as the reach or bendi/flexi truck.

Very Narrow Aisle (VNA) – The need for specialist trucks with guidance means the initial investment would be higher than that of the NAR system, however the efficiency gains and space saved in the long run makes it a worthy investment.

5.) Operational Efficiency

Narrow Aisle Racking (NAR) – Pallet placement and retrieval requires a little more care as operators navigate the narrowed aisles and this can make the process slower when compared to navigating the wide aisle racking aisles.

Very Narrow Aisle (VNA) – The use of specialised handling equipment between the closely configured racks increases pallet placement and retrieval times and although the specialist trucks are less efficient beyond the aisles, the option to incorporate pick and deposit stations P&Ds can resolve this issue and increase speed and efficiency across the entire operation and minimal risk of damage.

Optimal use of height space whilst utilising floor space is an advantageous offering by both the narrow aisles (NAR) and very narrow aisle (VNA) systems, however choosing the system most suited to your needs will depend on your available space, budget, and desired efficiency levels. WSL’s pallet racking design experts can offer a great deal of assistance when deciding on the most effective option for your operation.

The benefits of the narrow aisle racking configuration

Combining narrowed aisles with taller racks is a notably practical and widely favoured strategy. Without broadening the physical footprint of the occupied area, it enables the warehouse to expand its storage capacity, improve efficiency, and promote organisation.

However high the racks or however slim the aisles, a narrow aisle racking configuration will enable you to:

Boost storage capability – Reducing the width of aisles between rack rows allows for extra rows. When coupled with extending rack height through additional levels, storage capacity can be significantly increased.

Utilise unused height space – Height space holds just as much value as floor space and equally, it can be used to promote efficiency within the warehouse space. Taller racks make vertical space valuable, especially when dealing with limitations in floor space.

Access every pallet directly – As a high-density storage solution without the deep lanes lined with a que of pallets, the narrow aisle racking configuration can offer 100% selectivity. There is no pallet hidden behind another pallet and from the narrow access aisle, every pallet is visible, and any chosen pallet can be directly picked.

Save money – Narrower aisle width and taller racks can promote a significant increase in storage capacity whist the physical surface area remains the same. There is no need for a costly building extension or the financial burden of relocating to a larger space.

Maintain your carbon footprint – Because the narrow aisle configuration provides extra storage capabilities within a smaller warehouse, there is no requirement for extra energy usage, therefore your carbon footprint won’t increase, even if storage capacity does. This is an improved use of space which can assist your eco-friendly warehouse goals.

Improve efficiency – During demand peaks or general growth, limited floor space may impede efficiency, however the ability to stack pallets to an increased height level will help alleviate those challenges. With additional storage locations, pallets can remain organised and managed effectively with streamlined placement and retrieval.

Promote safety – Collisions are less likely due to no room for multiple vehicles moving in multiple directions within the aisle at the same time. Instead, trucks move with precise alignment between the rows of a racking system which is designed to promote safety and efficiency during the handling of goods. This is promoted by the perfectly flat and smooth floor surface area, the guided wires or rails and heightened operator visibility enable by side seating positions, cameras, or the ability to use the man-up mechanism, depending on the aisle width and suitability of the truck.

Planning points for a narrow aisle system:

Whilst the narrow aisle racking option has much to offer, it’s important to consider the following:

How generous is your height and floor space? – The higher the warehouse roof, the more advantageous a narrow aisle system will be. If both floor and hight space are limited, other more compact configurations such as pallet live racking which adopts deep lane storage may be a more suitable option.

What is the condition of your floor surface? – Installing taller racks on an uneven floor surface can cause tilts which can become a safety hazard, particularly as the reach truck nears the top. Both the truck and rack must be perfectly level during operation. In instances where the floor is uneven, work should be carried out to create a smooth, flat surface.

What is your budget? – Where specialist VNA trucks are required, this can come at a cost and whilst this is a cost this is likely to be returned through enhanced efficiency and safety, the initial investment would need to be factored into the cost of the new system.

What type of products will you be storing? – If pallet sizes are changeable and not uniformed the narrow aisle configuration may not accept some of the irregular shaped or sized units.

What are the required speed and efficiency levels? – When operating within the racks, specialist wire guided trucks are highly efficient, however their efficiency levels can drop as they veer away from the aisle. These trucks are better placed within the racks whilst the standard counterbalance truck is the most efficient option for pallet transportation beyond the racks. As these trucks are too wide to enter the racks, the two trucks can work together without entering each other’s most efficient spaces. Pick and deposit stations (P&Ds) can help streamline this process as they provide a dedicated place reachable by both trucks from their own areas where pallets can be placed to exchange handling from one truck to the other.

Considering narrowed aisles and taller racks?

Concerned about cramped aisles and unused overhead space in your warehouse? Wondering if a narrow aisle racking setup could be the answer? Contact our WSL design team today! Providing some essential information will enable us to offer you an initial budget estimate, or if you prefer, we can create a comprehensive plan and quote. Whatever your preference, we’re here to assist you in choosing the optimal solution for your space, operational requirements, and budget.

Detracting from the main point – a side note from the editor.

If you designate an area at the front of your racking for marshalling or block storage (even in a typical wide aisle system), chances are you’re not fully maximising the space above it. So, why not install a mezzanine floor (we provide these too! design, manufacture and install) so you can capitalise on even more available space?

Whatever your storage needs, reach out to us by calling 0113 2045350 or email sales@wslmail.co.uk